One of the traditional welder’s most closely guarded secrets is his jig. Often custom made, it is key to both bending metal and cutting and connecting all the pieces required for any kind of project, big or small. But technology has taken over, and the contemporary welder has the advantage of being able to use the most sophisticated welding jigs, clamps, stops, angles and support elements available today.

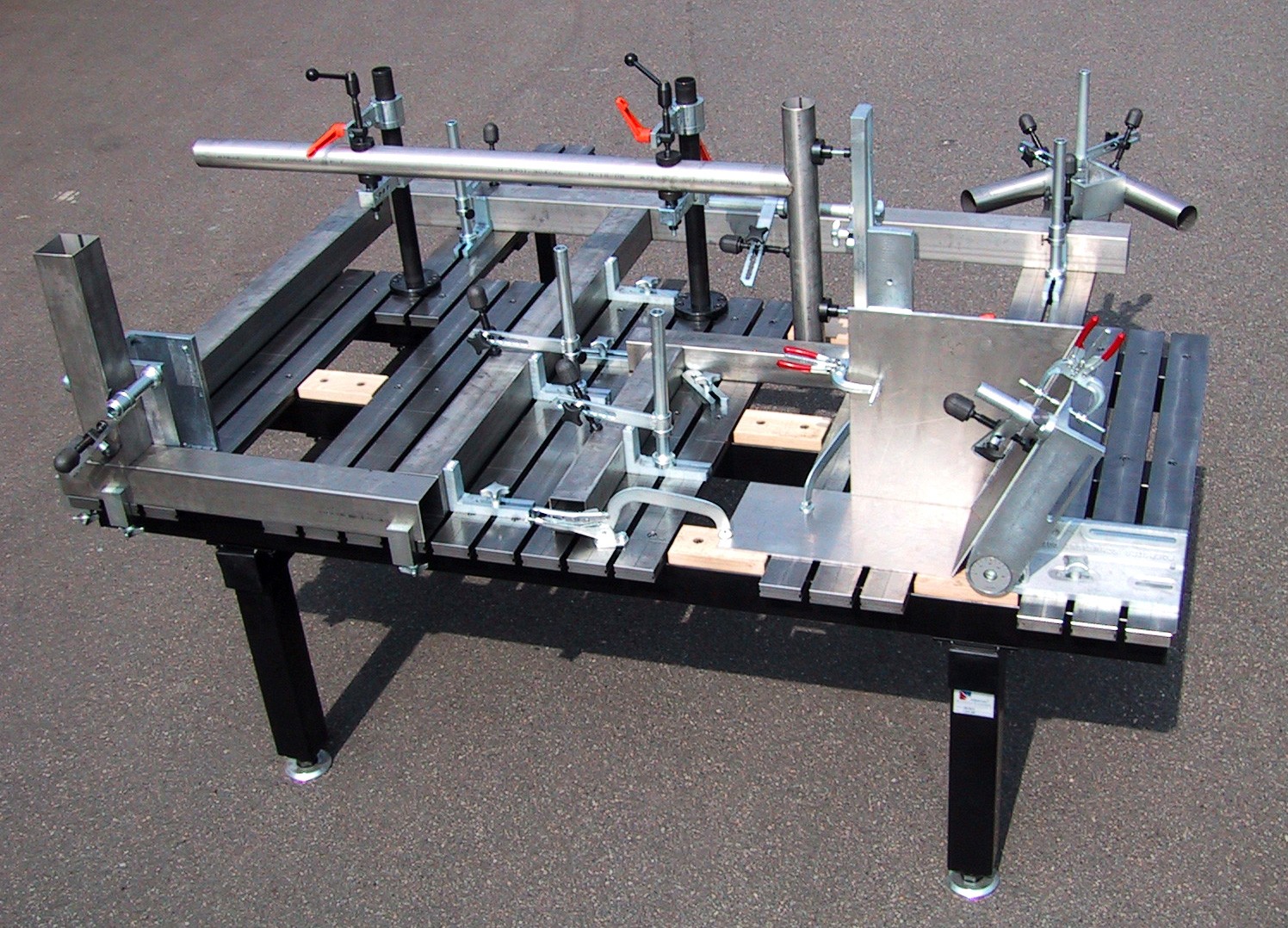

Leading manufacturer and supplier of sophisticated welding jigs, Forster America has a wide range of unique fixtures, tools, and accessories that are designed for use with their cutting-edge welding equipment including modular welding tables, frame welding fixtures, rail and fence railing fixtures, and lift, turn and tilt welding tables. These make the old-fashioned welding jigs, made for purpose by welders, redundant.

The value of these sophisticated welding jigs, tools, fixtures, and accessories is that they enable welders to accommodate workpieces of different shapes and sizes, and they can be used to create unique solutions for all their welding needs. They also enable welders to work faster, more easily, and with ultimate accuracy.

Equipment Sets

Welding jigs are essentially tools or devices that are used to hold components in place for cutting and welding. Forster’s range of equipment sets do this and more.

Welding jigs are essentially tools or devices that are used to hold components in place for cutting and welding. Forster’s range of equipment sets do this and more.

For example, sophisticated equipment sets for stainless steel rack and case manufacturing contain absolutely everything a welder in this industry niche needs including:

- Clamping arms, clamping columns and clamping towers

- Adjustable flat clamps and flat stops

- Aluminum try-squares of various sizes

- Right-angled brackets and support arms

- Double slot profiles each with two screws and two T-nuts for assembling on a try-square

- A continuously adjustable angle and universal angles

There are also very similar equipment sets for rack and case manufacturing with other metal materials that contain the same kinds and numbers of tools and accessories.

Equipment sets for manufacturing stainless steel frames are also similar. They come with a number of bronze-pad clamping arms, flat chromed steel clamps, and precision steel clamping columns, aluminum-finish universal angles, and flat stops, try-squares, edge angles, and quick release clamps, all made of aluminum.

Equipment sets for manufacturing frames made of other types of metal contain everything required for this type of welding including flat clamps, clamping arms and columns, flat clamps and stops, try-squares, edges and universal angles, and quick release clamps with flat stops.

Equipment sets for both stainless steel universal manufacturing and for universal manufacturing using other metals. Both containing multiple clamps, stops, supports, try-squares, and other items.

Equipment sets for stainless steel tube manufacturing that contain all the tools and fixtures needed for successful stainless steel tube manufacturing. Like the other jigs and equipment sets, these work exceptionally well with Forster’s 3D welding systems and are uniquely versatile.

Equipment sets for tube manufacturing using metals other than stainless steel, also with the full range of tools and other equipment.

A wide variety of clamping elements, as well as angles, support elements, and clamping columns and clamping arms, are available separately, enabling welders to access every part of their welding tables without any effort.

Whether you need a sophisticated 3D welding system or just equipment sets that will enable you to set up your own unique jig, Forster America is certain to have exactly what you need. Give us a call today.

Imagine a welding table with a surface that moves exactly the way you need it to so that you can adjust the position of your workpiece. Imagine a welding table that uses a specialized lift, horizontal rotary, or vertical turntable that will cope with any possibility you might face when doing a customized project.

Imagine a welding table with a surface that moves exactly the way you need it to so that you can adjust the position of your workpiece. Imagine a welding table that uses a specialized lift, horizontal rotary, or vertical turntable that will cope with any possibility you might face when doing a customized project. Ergonomics, as a science, strive to ensure we use less physical effort to do things. By minimizing strain, ergonomics help to keep our bodies healthy and more relaxed. Welding equipment that is designed to help people work more ergonomically is not only better for their physical health, but it will also improve productivity.

Ergonomics, as a science, strive to ensure we use less physical effort to do things. By minimizing strain, ergonomics help to keep our bodies healthy and more relaxed. Welding equipment that is designed to help people work more ergonomically is not only better for their physical health, but it will also improve productivity. Forster America offers frame welding and railing welding fixtures that enable workers to make quick, easy adjustments on all four sides of rectangular frames. The most significant advantage is that all angles are exposed, making them easily accessible.

Forster America offers frame welding and railing welding fixtures that enable workers to make quick, easy adjustments on all four sides of rectangular frames. The most significant advantage is that all angles are exposed, making them easily accessible. A modular welding table from Forster America will undoubtedly help you to up your game. But it gets better than that. The company’s equipment sets provide a versatile way to customize your welding table with clamping systems and various brackets and supporting arms, depending on your needs. Sets are available for steel, for universal welding, for frame welding, pipework, and for rack and case. Take your pick.

A modular welding table from Forster America will undoubtedly help you to up your game. But it gets better than that. The company’s equipment sets provide a versatile way to customize your welding table with clamping systems and various brackets and supporting arms, depending on your needs. Sets are available for steel, for universal welding, for frame welding, pipework, and for rack and case. Take your pick. There are various types of cast iron all of which are alloys of iron, carbon (usually between 1.7 and 4.5 percent), and silicon.

There are various types of cast iron all of which are alloys of iron, carbon (usually between 1.7 and 4.5 percent), and silicon. When welding with stainless steel the best results will be produced by working on non-ferritic surfaces that do not contain iron. Ferrous metal surfaces can result in scratches to the stainless steel work piece and sometimes even more severe pitting.

When welding with stainless steel the best results will be produced by working on non-ferritic surfaces that do not contain iron. Ferrous metal surfaces can result in scratches to the stainless steel work piece and sometimes even more severe pitting. Different welding jobs have different demands. Some are quite routine and relatively simple while others are highly complex and complicated. Historically this has meant that companies offering welding services have had to ensure that there are multiple welding tables or a number of different welding stations that can cope with work pieces of different sizes as well as different metals.

Different welding jobs have different demands. Some are quite routine and relatively simple while others are highly complex and complicated. Historically this has meant that companies offering welding services have had to ensure that there are multiple welding tables or a number of different welding stations that can cope with work pieces of different sizes as well as different metals.

Forster America has a height-adjustable welding table solution for bad posture in the welding environment. Recognizing that good posture is virtually impossible with regular non-adjustable welding tables, the company now manufactures Ergofix, a state-of-the-art welding “manipulator” that is infinitely adjustable in height. Better still, it can be rotated a full 360 degrees and tilted up to 45 degrees.

Forster America has a height-adjustable welding table solution for bad posture in the welding environment. Recognizing that good posture is virtually impossible with regular non-adjustable welding tables, the company now manufactures Ergofix, a state-of-the-art welding “manipulator” that is infinitely adjustable in height. Better still, it can be rotated a full 360 degrees and tilted up to 45 degrees.