Case Studies

CDE Fabrication

CDE Fabrication

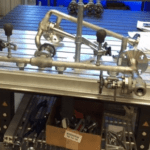

CDE Fabrication was searching for a better efficient clamping system and safer surface interaction for welding stainless steel and standard steel pipe welding projects. Their current hole-pattern table design did not have the versatility that what was needed for all of their projects. He was looking for a table that could accommodate several different projects.

CDE chose a Forster Al-Cu alloy T-Slot Welding Table designed specifically for accurate stainless steel welding projects. Since the Forster modular table surface rails can be replaced or moved quickly we also decided to split CDE Fabrication’s table into two halves. One with Al-Cu alloy surface rails for his stainless steel projects and the other comprised of Grey Cast Iron T-Slot surface rails for his more standard steel welding projects. The surface rails are designed to be moved left or right for the welder to accommodate wider or longer length projects on a smaller base table size.

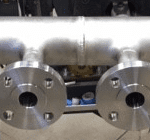

Additionally, CDE Fabrication selected height and angle adjustable Forster v-blocks to place the pipe into an exact position quickly. The T-Slot system allows the operator to locate the clamps or brackets quickly because they can be moved along the x and y-axis simultaneously.

Click images to view larger.

Challenges

- To buy one table to support multiple project sizes and multiple metal types including stainless steel. Also, discover which clamping or supporting tools would work best for holding his pipe projects above the table surface and create vertical slope pipe clamp systems.

Alliance Systems

Alliance Systems

This client’s engineering department was tasked with improving the company’s welding setup time and efficiency.

The welders we spending too much time re-positioning and re-measuring their projects with poor tooling. They needed to find a solution that would meet their ROI number, get projects out the door, and reduce errors. They wanted to install equipment in all areas of production to meet their goal.

Challenges

- This client needed to improve overall welding setup and efficiency of welding projects.

- Client had an ROI goal that needed to be met.

Result

- In 2 months this client determined that they are saving an hour per shift.

- The ROI for their new equipment is just 3.1 months.

PD Blowers

PD Blowers

This client was having trouble meeting their completion standards and production deadlines using the equipment they had.

They have installed a total of 4 new welding tables designed to meet their versatile welding needs, this saves them 25hrs. per base.

Read PDBlowers Non-Elevated Steam Base Time Study Here (.PDF)

Project Gallery

Challenges

- Client was behind in production to meet their completion standards.

- They were using hole patterned weld tables and saw horses with basic clamps to set up/weld their versatile projects.

Result

- This client improved their welding time per base by 25 hrs, essentially a 100 hr improvement in productivity.

- They continue to increase their efficiency requirements by employing additional Forster Products.