Forster 3D Welding Systems has a long, successfully history that includes a number of prestigious awards for their innovative, world-class products.

Forster America caters for a wide range of industries, from aviation, and automotive and transportation industries, to construction-orientated industries that manufacture frames, doors, and windows, as well as railings, fences, and gates.

The company specializes in 3D equipment, particularly modular welding tables and an ingenious 3D clamping system, as well as a state-of-the-art lift, turn, and tilt welding tables and a range of technologically advanced frame welding fixtures, jigs, and welding tools.

Awards Achieved by Forster 3D Welding Systems

Top achievements of the company in terms of awards include:

- VR Förderpreis Handwerk, a promotional award made annually by the Volksbanken Raiffeisenbanken Cooperative Financial Group

- The Bavarian State Prize in 1997 (gold medal)

- The Bavarian State Prize in 2002 (gold medal)

- The Bavarian Federal Prize in 2011

The prestigious Bavarian State Prizes are awarded by the Bavarian State Government’s Ministry of Economic Affairs in Germany for highly creative and technologically advanced performance in “craft trades.”

Historically, craft trades were professions that required specific knowledge and skills to undertake and achieve. Recipients nowadays are leading companies that have achieved innovative cutting-edge solutions.

The awards are presented at the annual International Industry and Craft Fair in Munich (IHM) in recognition of outstandingly innovative achievements in various categories including trade, industry, commerce, and services. Generally, recognition is an acknowledgment that the companies that receive the awards are very likely to have long-term economic success.

This is certainly true for Forster America.

The Federal Prize

The most recent award received by Forster 3D Welding Systems was the Federal Prize awarded in 2011 for the company’s railing welding gauge designed for double-sided welding with a bar division.

The award, which includes a cash prize of 5,000 euros was first presented in 1989.

The Bavarian State Prize

Forster 3D Welding Systems was first awarded the Bavarian State Prize Gold Medal in 1997 for the “Forster Welding Table as a construction kit and clamping system for T-slot system.”

Forster’s innovative 3D modular welding tables feature a hugely versatile T-slot tabletop that allows welders to work with the equally innovative 3D clamping system.

The T-slots on the table surface can be adjusted so that components can be used to prepare for under undertake precision welding. The clamping system incorporates a wide range of elements including angles and supports, clamping arms and columns, as well as stops.

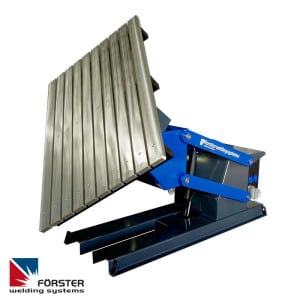

Forster won the Bavarian State Prize Gold Medal a second time in 2002. This time it was awarded for the innovative ErgoFix Manipulator, which is an ergonomic rotating, lifting, and tilting welding fixture.

Essentially a very sophisticated welding table, the ErgoFix can be rotated 360 degrees, tilted to 45 degrees, and it is infinitely adjustable in terms of height. Apart from the fact that it enables welders to access every part of the workpiece being welded, it ensures that users maintain an ergonomic posture while they work. Not only is this the best option for good health, but it also encourages optimal welding results.

The VR Prize

This prize is awarded by Volksbanken Raiffeisenbanken Cooperative Financial Group to companies that “do an excellent job as an employer to strengthen their region.” The award is in the form of a loan that is intended to promote the business.

It was also awarded for the “Forster Welding Table as a construction kit and clamping system for T-slot system.”

Forster America’s Award-Winning Products Are Available for Your Welding Business

If you want to improve the equipment in your welding workshop, Forster America’s 3D modular welding tables, 3D clamping system, and ErgoFix Manipulator are a good place to start.

Call us today if you want more information.

Imagine a welding table with a surface that moves exactly the way you need it to so that you can adjust the position of your workpiece. Imagine a welding table that uses a specialized lift, horizontal rotary, or vertical turntable that will cope with any possibility you might face when doing a customized project.

Imagine a welding table with a surface that moves exactly the way you need it to so that you can adjust the position of your workpiece. Imagine a welding table that uses a specialized lift, horizontal rotary, or vertical turntable that will cope with any possibility you might face when doing a customized project. Ergonomics, as a science, strive to ensure we use less physical effort to do things. By minimizing strain, ergonomics help to keep our bodies healthy and more relaxed. Welding equipment that is designed to help people work more ergonomically is not only better for their physical health, but it will also improve productivity.

Ergonomics, as a science, strive to ensure we use less physical effort to do things. By minimizing strain, ergonomics help to keep our bodies healthy and more relaxed. Welding equipment that is designed to help people work more ergonomically is not only better for their physical health, but it will also improve productivity. Forster America offers frame welding and railing welding fixtures that enable workers to make quick, easy adjustments on all four sides of rectangular frames. The most significant advantage is that all angles are exposed, making them easily accessible.

Forster America offers frame welding and railing welding fixtures that enable workers to make quick, easy adjustments on all four sides of rectangular frames. The most significant advantage is that all angles are exposed, making them easily accessible. A modular welding table from Forster America will undoubtedly help you to up your game. But it gets better than that. The company’s equipment sets provide a versatile way to customize your welding table with clamping systems and various brackets and supporting arms, depending on your needs. Sets are available for steel, for universal welding, for frame welding, pipework, and for rack and case. Take your pick.

A modular welding table from Forster America will undoubtedly help you to up your game. But it gets better than that. The company’s equipment sets provide a versatile way to customize your welding table with clamping systems and various brackets and supporting arms, depending on your needs. Sets are available for steel, for universal welding, for frame welding, pipework, and for rack and case. Take your pick. Different welding jobs have different demands. Some are quite routine and relatively simple while others are highly complex and complicated. Historically this has meant that companies offering welding services have had to ensure that there are multiple welding tables or a number of different welding stations that can cope with work pieces of different sizes as well as different metals.

Different welding jobs have different demands. Some are quite routine and relatively simple while others are highly complex and complicated. Historically this has meant that companies offering welding services have had to ensure that there are multiple welding tables or a number of different welding stations that can cope with work pieces of different sizes as well as different metals.

Forster America has a height-adjustable welding table solution for bad posture in the welding environment. Recognizing that good posture is virtually impossible with regular non-adjustable welding tables, the company now manufactures Ergofix, a state-of-the-art welding “manipulator” that is infinitely adjustable in height. Better still, it can be rotated a full 360 degrees and tilted up to 45 degrees.

Forster America has a height-adjustable welding table solution for bad posture in the welding environment. Recognizing that good posture is virtually impossible with regular non-adjustable welding tables, the company now manufactures Ergofix, a state-of-the-art welding “manipulator” that is infinitely adjustable in height. Better still, it can be rotated a full 360 degrees and tilted up to 45 degrees.

Forster’s hydraulic turn-tilt welding tables are designed for infinite three-axis adjustment of work pieces. As the name suggests, they can be easily turned and tilted, and their height can be controlled so that a perfect ergonomic position is achieved for welding. This enables welders to work fast and precisely and increases productivity, and therefore profitability as well.

Forster’s hydraulic turn-tilt welding tables are designed for infinite three-axis adjustment of work pieces. As the name suggests, they can be easily turned and tilted, and their height can be controlled so that a perfect ergonomic position is achieved for welding. This enables welders to work fast and precisely and increases productivity, and therefore profitability as well.

Forster’s three-axis positioners have a lifting function and two rotary axes. Like Forster’s turn-tilt tables, they are designed so they can be positioned for an ergonomic working height when welding. They are suitable for both manual and robotic welding and ideal for reaching welding seams easily and accurately when working in a flat position.

Forster’s three-axis positioners have a lifting function and two rotary axes. Like Forster’s turn-tilt tables, they are designed so they can be positioned for an ergonomic working height when welding. They are suitable for both manual and robotic welding and ideal for reaching welding seams easily and accurately when working in a flat position. The additional robot axes are even better for welding seams using either manual or robotic methods of welding. They have a similar lifting functionality as the axis positioners (1,100 mm) as well as a two-axis rotation that will enable workers to reach all the weld seams. Both horizontal and vertical axis rotation is the same (185 and 360 degrees) and the same collision protection is available.

The additional robot axes are even better for welding seams using either manual or robotic methods of welding. They have a similar lifting functionality as the axis positioners (1,100 mm) as well as a two-axis rotation that will enable workers to reach all the weld seams. Both horizontal and vertical axis rotation is the same (185 and 360 degrees) and the same collision protection is available. The rotation of the positioners allow a welder to weld seems in flat positions while being at an ergonomic working height. The versatile tables are customized to meet their client’s requirements and can be used for manual welding or welding robots as needed. Since the manipulators allow them to move the project where they need it rather than forcing the welder to keep changing position, it speeds up the process a great deal.

The rotation of the positioners allow a welder to weld seems in flat positions while being at an ergonomic working height. The versatile tables are customized to meet their client’s requirements and can be used for manual welding or welding robots as needed. Since the manipulators allow them to move the project where they need it rather than forcing the welder to keep changing position, it speeds up the process a great deal.