Welders working on large or complicated projects can improve quality, safety, and work ergonomics, and become substantially more efficient and productive if they use well-designed work piece manipulators.

Forster welding manipulator systems incorporate tilting tables that turn and lift, as well as 3-axis positioners, and additional robot axis devices that improve a welder’s ability to produce the very best items possible. Essentially these hi-tech tools enable welders to work at a height that is ergonomically proven and also reach all the weld seams in flat positions.

Welding work piece manipulators are invaluable because they may be used for manual welding and in conjunction with welding robots. They may also be customized. The chief value of manipulators and positioners is that they make the work piece more accessible, and in this way enable welders to speed up the welding process.

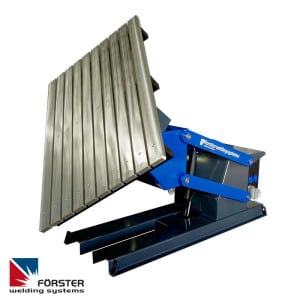

Turn-Tilt Tables

Turn-tilt tables are relatively small and compact, and ergonomically designed for adjustment of infinite three-axis work pieces. The beauty of them is that they can be turned and tilted, and the height adjusted, to ensure secure, accurate positioning for optimum working and welding positions. They are ideal for achieving optimum welding parameters and ensuring better quality with less surface finishing required. They are also precise, and particularly useful for fast downward seam welding.

All movements of turn-tilt tables are controlled, very easily, by hand and enable operators to monitor the way the table operates with a digital speed indicator. There is also an optional foot pedal for start-up, speed control, and for stopping. A wireless remote control is also available.

The tables are also safe, and they feature integrated safety valves that prevent hydraulic hoses being damaged.

Available in five different sizes, and from weights of 520 kg to 8,000 kg, Forster turn-tilt tables are suitable for loads from 8,000 N to 160,000 N (Newton’s unit of force.) They can carry work piece weights of between 800 kg and 16,000 kg,

Axis Positioners

Forster’s three-axis positioners have a lifting function and two rotary axes. Like Forster’s turn-tilt tables, they are designed so they can be positioned for an ergonomic working height when welding. They are suitable for both manual and robotic welding and ideal for reaching welding seams easily and accurately when working in a flat position.

Forster’s three-axis positioners have a lifting function and two rotary axes. Like Forster’s turn-tilt tables, they are designed so they can be positioned for an ergonomic working height when welding. They are suitable for both manual and robotic welding and ideal for reaching welding seams easily and accurately when working in a flat position.

Axis positioners can be used to lift the work piece up 1,100 mm. They can rotate 185 degrees on the horizontal axis and a full 360 degrees on the vertical axis. A position-limiting switch provides collision protection.

Forster America designs and manufactures positioners to meet very specific client needs, including handling large objects.

Additional Robot Axis Manipulators

The additional robot axes are even better for welding seams using either manual or robotic methods of welding. They have a similar lifting functionality as the axis positioners (1,100 mm) as well as a two-axis rotation that will enable workers to reach all the weld seams. Both horizontal and vertical axis rotation is the same (185 and 360 degrees) and the same collision protection is available.

The additional robot axes are even better for welding seams using either manual or robotic methods of welding. They have a similar lifting functionality as the axis positioners (1,100 mm) as well as a two-axis rotation that will enable workers to reach all the weld seams. Both horizontal and vertical axis rotation is the same (185 and 360 degrees) and the same collision protection is available.

Additional robot axes are commonly used for the production automation of high-volume components. A substantial amount of time is saved because they can be used as a moving work piece.

Without a doubt, Forster America can help any competitive welding business manipulate its work in the best possible way!